In the field of small-scale monitoring, traditional monitoring equipment is often limited due to its large size and excessive weight. The combination of the Tamron MP3010M-EV camera module and the VRS-UD350 LVDS/MIPI to network control board is breaking these limitations with its extreme lightness of 70 grams and the advantage of networked transmission.

I. Mini body, subverting the limitations of traditional monitoring equipment

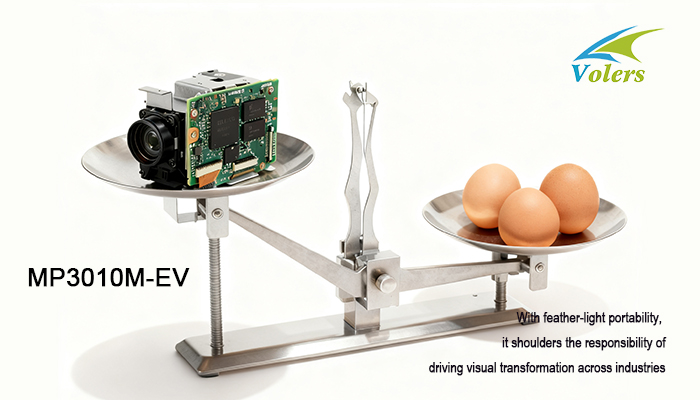

The weight of the Tamron MP3010M-EV is only 70 grams, and its dimensions are 33×43×59 millimeters, which is equivalent to the weight of an egg. This ultra-compact design enables it to be easily integrated into space-sensitive and load-bearing devices such as drones and pipeline robots.

In the scenario of drone inspection, this lightweight design directly enhances flight performance. After a certain agricultural drone was equipped with the MP3010M-EV, not only was the single flight time extended, but there was also space to additionally install an infrared thermal imager, achieving dual-mode inspection of “visible light + thermal imaging”, which significantly improved the accuracy of fault identification.

The 10x optical zoom capability enables this mini camera to capture clear images ranging from wide-angle to telephoto. The horizontal field of view from 6.7° (telephoto end) to 59.2° (wide-angle end) enables it to grasp both the overall scene and focus on minute details.

II, low power consumption and excellent environmental adaptability

The power consumption of Tamron MP3010M-EV in static operation is only 2.5W (about 4.4W in dynamic operation), which is attributed to its low-power CMOS sensor and precise power management chip. Its low power consumption feature makes it particularly suitable for security monitoring or industrial inspection equipment that needs to operate for a long time.

In terms of light adaptability, the Tamron MP3010M-EV performs exceptionally well. It adopts SONY STARVIS technology CMOS sensor, with a minimum illuminance of 0.1lx (color) / 0.025lx (black and white).

Its day-night switching function achieves a seamless transition from daytime color imaging to nighttime near-infrared imaging through the automatic removal of the mechanical infrared cut-off filter (ICR).

Wide Dynamic range (WDR) technology can balance the exposure differences between highlights and shadows, presenting complete image information even in strong light conditions.

The electronic image stabilization function compensates for high-frequency vibrations through algorithms, effectively suppressing image blurring caused by equipment vibration, and providing reliable visual protection for industrial environments with high-frequency operations.

Iii. Network interface Board: Empowering Remote High-Definition Transmission

The VRS-UD350 LVDS/MIPI to network interface board is the key to the network upgrade of the Tamron MP3010M-EV. By connecting the LVDS output port of the MP3010M-EV via a 30-pin ribbon cable, this control board can encode 1080P/60fps video streams in real time into RTSP/ONVIF protocol IP signals and achieve remote transmission via Ethernet.

The traditional monitoring system is limited by the length of cables, while the VRS-UD350 breaks the physical distance limitation through networked transmission. Users can directly control the camera module through the network IE interface to remotely adjust parameters such as zoom, focus, and exposure.

The VRS-UD350 LVDS/MIPI to network control board supports H.265/H.264 dual-stream encoding, which can compress video streams to a lower bandwidth and is compatible with 5G/4G network transmission. It is very suitable for remote inspection needs in remote areas.

IV. Multi-scenario Applications: Small size solves big problems

Industrial inspection and Automation: In the field of precision manufacturing, the ultra-compact design of the MP3010M-EV can be easily integrated into narrow production lines. Capturing minute pin welding defects through 10x zoom can significantly reduce the rate of missed detections.

Pipeline robots and confined space inspection: Traditional camera equipment, due to its heavy weight and insufficient zoom capability, causes the robot to move slowly. The lightweight and zoom combination of the MP3010M-EV endows robots with “superpowers”, significantly enhancing detection efficiency.

Security monitoring: In traffic monitoring scenarios, the wide dynamic range technology of the Tamron MP3010M-EV can clearly present the reflective area of the license plate and the facial features of the driver simultaneously at intersections directly exposed to strong light.

Unmanned aerial vehicle (UAV) inspection: Equipped with the VRS-UD350 LVDS/MIPI network control board, the UAV can achieve digital transmission of high-definition video, providing visual support for remote monitoring and decision-making.

Conclusion: Lightweighting drives a new era of monitoring

The combination of Tamron MP3010M-EV and LVDS/MIPI to network control board represents the major trend of monitoring systems moving towards lightweight, networking and intelligence. This combination addresses the pain points of traditional monitoring equipment in terms of space limitations, power consumption control and remote transmission.

When a 70-gram device can achieve the functions of previous large-scale monitoring systems, we can’t help but rethink where the boundaries of monitoring equipment lie. This is not merely a technological upgrade, but also a conceptual innovation on how to “see” the world more efficiently and intelligently.

Lighter than a feather but heavier than Mount Tai – the Tamron MP3010M-EV is shouldering the responsibility of visual transformation in all industries with the lightness of an egg.

Sony FCB camera block

Sony FCB camera block