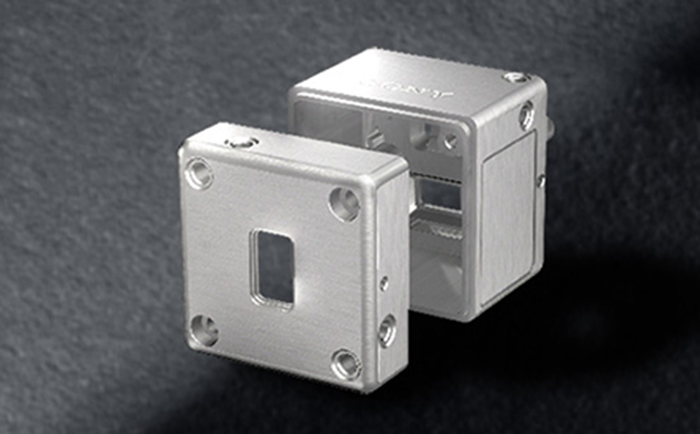

The SONY AS-DT1 lidar depth sensor adopts an aluminum alloy housing design. This design not only enhances the overall performance of the product but also brings many significant advantages to practical applications.

1. Lightweight

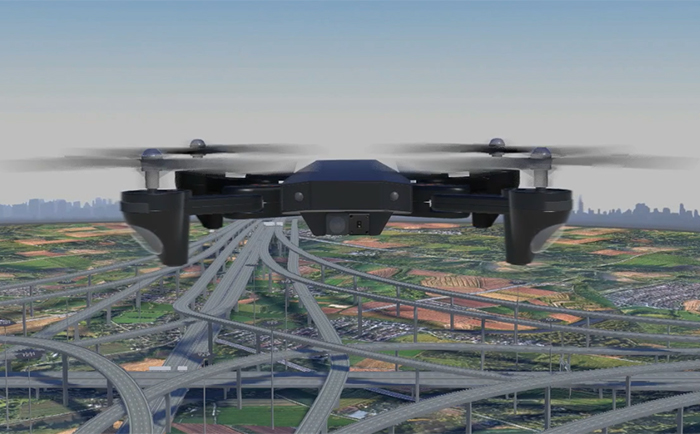

Aluminum alloy is a lightweight material, and its density is only about one-third that of steel. This enables the SONY AS-DT1 to significantly reduce its own weight while maintaining high strength. For weight-sensitive application scenarios such as drones and robots, lightweight design can significantly enhance the battery life and flexibility of the equipment.

2. High strength

Although the density of aluminium alloy is relatively low, its strength is very high. The aluminum alloy housing of SONY AS-DT1 can withstand significant mechanical shock and pressure, ensuring the stability and reliability of the sensor in complex environments. This high-strength design enables the sensor to maintain normal operation under various harsh conditions.

3. Good heat dissipation performance

Aluminum alloy has excellent thermal conductivity and can effectively conduct and dissipate the heat generated by the sensor during operation. This not only helps to extend the service life of the SONY AS-DT1 lidar sensor, but also ensures its stable operation in high-temperature environments. Good heat dissipation performance is crucial for high-precision measurement and long-term continuous operation.

4. Corrosion resistance

A dense oxide film usually forms on the surface of aluminum alloy, which can effectively prevent further oxidation and corrosion. This corrosion resistance enables SONY AS-DT1 to operate stably for a long time in harsh environments such AS humidity and salt spray, reducing equipment failures caused by environmental factors.

5. Aesthetics and durability

The aluminum alloy shell not only has excellent mechanical properties but also an attractive appearance. Its surface can undergo various treatments, such as sandblasting and anodizing, to enhance the overall texture and durability of the product. This design of SONY AS-DT1 not only enhances the aesthetic appeal of the product, but also strengthens its adaptability in various application scenarios.

6. Easy to process and shape

Aluminum alloy has excellent processing performance and can be made into complex shapes through various processing methods, such as casting, extrusion, stamping, etc. This enables the housing of SONY AS-DT1 to be optimized according to the internal structure of the sensor, achieving a compact size and good mechanical performance.

7. Environmental friendliness

Aluminum alloy is a recyclable material with a high recycling rate and a relatively small impact on the environment. The use of an aluminum alloy shell not only meets environmental protection requirements but also reduces the full life cycle cost of the product.

Summary

The SONY AS-DT1 lidar depth sensor adopts an aluminum alloy housing design, which not only realizes the dual advantages of lightweight and high strength, but also has good heat dissipation performance, corrosion resistance and aesthetics. These advantages enable AS-DT1 to perform well in application scenarios such AS unmanned aerial vehicles and robots that have high requirements for weight and environmental adaptability, providing reliable technical support for future intelligent devices.

Sony FCB camera block

Sony FCB camera block