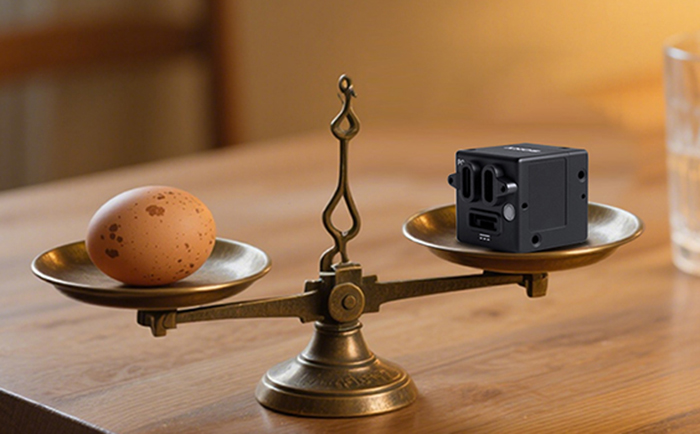

In cutting-edge fields such as autonomous driving, unmanned aerial vehicle (UAV) inspection, and industrial testing, LiDAR has long become the “eye for perceiving the world”. However, traditional LiDAR often falls into the predicament of “ignoring” when facing low-reflectivity objects such as dark roads, glass curtain walls, and plastic packaging, as well as suspended targets like flying birds, drones, and falling objects from heights. The revolutionary technological breakthrough of SONY AS-DT1 has brought about a qualitative leap in the perception capabilities of LiDAR – even in the most challenging detection scenarios, it can achieve high-precision perception.

I. The Fatal Bottleneck of Traditional LiDAR: Low Reflectivity and the “Perception Black Hole” of Suspended Targets

Traditional lidar generates point clouds by relying on the reflection intensity of laser pulses on the surface of objects. However, low-reflectivity objects (such as black tires and dark clothing) and suspended targets (such as cables and branches) have weak reflection signals, resulting in sparse or even missing point clouds.

Comparison of measured data

Ordinary LiDAR: The detection distance for transparent glass is relatively small, and the missed detection rate is relatively high.

Identification of suspended cables: The point cloud breakage rate is relatively high, and continuous trajectories cannot be generated.

The pain points in the industry lie in the fact that signal attenuation (such as laser scattering in rainy days) and background noise (such as strong sunlight interference) further amplify errors.

Ii. Technological Breakthrough: The Synergistic Revolution of SPAD Sensors and dToF

1. Single-photon level detection: The “Super-sensitive Eye” of SPAD sensors

The single-photon avalanche diode (SPAD) equipped on SONY’s A-DT1 lidar amplifies a single photon signal through the avalanche multiplication effect, breaking through the sensitivity limit of traditional APD/PIN diodes.

Three-dimensional point cloud layering: The dense ranging of 576 points per frame (24×24 array) can distinguish the shelf partitions from the suspended objects above, preventing the robotic arm from mistakenly grasping.

2. Stable output under extreme lighting conditions

From the 100,000 lux of strong light outdoors in summer to the low-light environment in warehouses, the AS-DT1 achieves reliable all-weather operation through dual-mode light emphasis nodes and SPAD sensitivity optimization:

(1) Strong light suppression technology

940nm band anti-glare: Select the near-infrared invisible light band to avoid strong interference in the solar spectrum (such as water surface reflection, glass curtain wall glare), and still maintain ± 5cm accuracy when measuring distances from 20 meters outdoors.

Automatic Gain Control (AGC) : Dynamically adjust the laser emission power based on the intensity of ambient light to prevent sensor saturation and failure in strong light environments.

(2) Weak light enhancement scheme

SPAD single-photon sensitivity: In an underground parking lot without auxiliary lighting (< 1 lux), it can still detect the reflected signal of metal shelves, with a ranging error of less than 8 cm (at a distance of 10 meters).

Iii. Scenario Implementation: Security Protection in Multiple Scenarios

1. Autonomous driving: Real-time early warning of transparent obstacles in tunnels

The new autonomous driving navigation system, combined with SPAD LiDAR, can successfully identify discarded transparent mineral water bottles in tunnels and trigger emergency braking, shortening the distance.

Port AGV: SONY AS-DT1 can precisely locate the lock of suspended containers in backlit conditions, which can enhance loading and unloading efficiency.

2. Unmanned aerial Vehicle power inspection: Precise detection of broken cable strands

In the unmanned aerial vehicle (UAV) power inspection industry, if SONY’s AS-DT1 lidar sensor is adopted, it can achieve dynamic tracking of the arc of high-voltage cables and identify subtle strand damage.

3. Industrial robots: Grasping flexible objects in dark environments

The dark parts on the black rubber conveyor belt are transformed into complete 3D models through SPAD point clouds, significantly enhancing the success rate of grasping.

Conclusion: From “Blindness” to “Perspective”, Redefining the boundaries of machine perception

When the laser penetrates the dark tires and captures every tremor of the suspended cables, what we see is not only a technological victory but also the absolute reliability of the unmanned system in high-risk scenarios. In the future, with the large-scale production of SPAD and the maturation of quantum dot optical coating technology, SONY’s AS-DT1 lidar sensor will be AS “fearless of night and backlight” as human vision, becoming the third eye of the intelligent world.

There are no miracles in technology; only the trajectory of ultimate innovation exists.

Sony FCB camera block

Sony FCB camera block